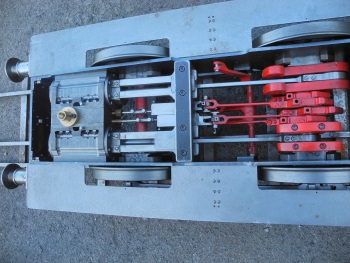

71/4" GWR '6412' Pannier Tank loco chassis

SOLD - two of these identical rolling chassis.

Built to a very high standard, these have both been run on compressed air and found to be good, with no unexpected rattles, and no 'tight spots'!

Click on any picture to load a larger image.

The cylinders were made from continuous cast iron bar, 3" square. This stuff cuts nicely using an ordinary hack saw - far less work than you might imagine!

There are other loco designs with a similar motion, 'Dart' by Martin Evans is one such, 'Dean Goods' by K Wilson is another. A common criticism of 'Dart' is that it is under-powered for a loco of its size. This is because using cylinder castings with steam passages drilled at an awkward angle, the bore has to be made much smaller than scale. This problem has been avoided by a well thought out fabrication method where passages are parallel to the bores, which are to scale (well, very nearly).

Design is from GWR Swindon drawings, supplemented by photos and measurements taken from original GWR '6412' when stabled on the WSR, all drawings used including CAD files generated included in the sale.

Previously offered for sale at a much higher price elsewhere, asking price now reduced to £ ??? THE PAIR - Now SOLD!

Two more recent photos, there is one smokebox assembly finished and shown here, the other is not painted and the door is not hung, but both have complete chimneys including profile-hugging CNC machined bases.

Details of the cylinder assembly construction, there are five pieces of cast iron in the sandwich instead of the more usual three (being two cylinders and one steam cheat). The two extra pieces are plates about 5mm thick. These have the steam passages milled into them so making the passages parallel to the bores. Rather than the more usual drilling of steam passages at an angle, this method enables the bores to be very close to true scale size. Other designs such as Martin Evans' 'Dart' have bores very much undersized.

Valve gear is Stephensons as per prototype. The eccentrics were jig machined with a locating pin hole. This enabled assembly of eccentric pairs with the exactly desired angle between them. The pins extend into the crank webs so fixing the eccentrics into the correct position once and for all - no tiresome adjustment is necessary or indeed even possible.

The crank pins have roller bearings, the same as the axleboxes. This design idea was stolen from K Wilson's design 'Dean Goods'.

Working from original GWR Swindon drawings, the models use a scale of 0.128, adjusted where needed for a practical build.

The horns were finished to size as shown using the milling machine. This guarantees axle spacing at exactly 11.250". Machining of the coupling rods was also done on the mill so that they fitted perfectly, the wheels all rotate with no tight spots.

Started in 2001, the first task was to draw the frames using AutoCAD (2002LT) to produce files for the frames, buffer beams and other parts to be laser cut.

Reason for sale, the realisation that locos in this scale are just too big and heavy for me, gone back to 5".