'The Wedge' - A New Electric 5"G Loco using Brushless Motors !

Summary of articles published in 'Engineering in Miniature', Oct Nov Dec 2015

It's time for a fresh look at Electric Loco Design.

Motors using 'brushes' will soon be a thing of the past.

Brushless motors are simpler, more reliable and are smaller and lighter for any given power. They use electronic controllers to create rotating magnetic fields in the fixed motor windings. This rotating field pulls the magnetic rotor around with it. That's brushless motors in a nutshell !

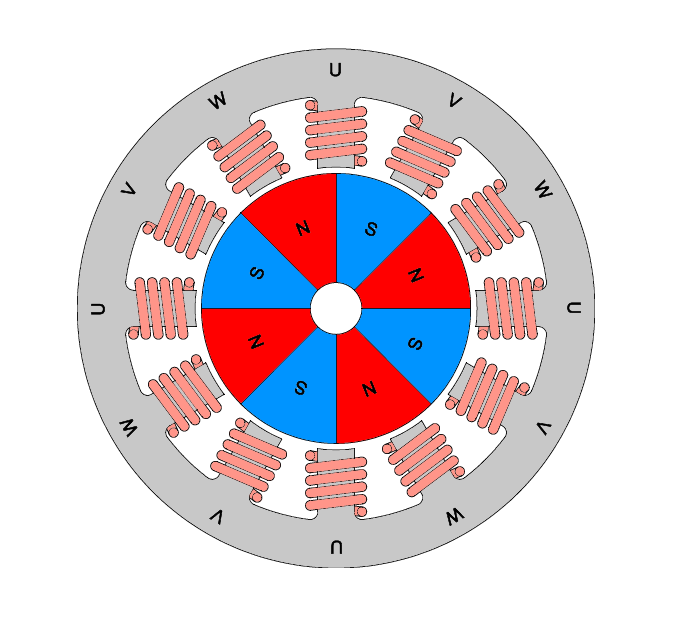

Often known as Brushless DC motors (BLDC), the first thing to realise is the BLDC motor is not a DC motor at all, it is a three-phase AC motor, but don't let that put you off. Using sensors fitted to the rotor which provide shaft-angle feedback, the method of control is almost unbelievably simple and elegant.

Quite simply, when driving the motor, the electronics uses fast electronic switches to connect one of U, V, or W to the positive side of the power supply, another of U, V or W to the negative side, leaving the third disconnected. By repeatedly running through a sequence of six switch settings a rotating magnetic field is created in the stator. This pulls the magnetic rotor around. The "Hall Effect" sensors provide signals back to the controller indicating rotor angle. The signal changes once for every 15 degrees of rotation in the case of the 8 pole motor shown. This 'change' signal causes the electronics to switch the power to pull the rotor into the next segment.

Update October 2015

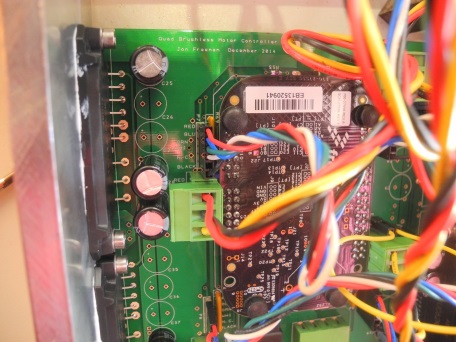

Lots more detail to be read in the articles published in 'Engineering in Miniature', for any further info on the electronics and software, please use the contact details below and ask.

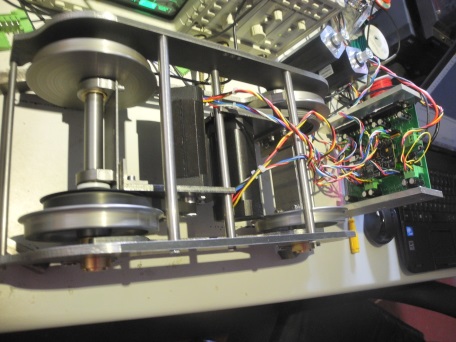

In action, the first run video, March 2015, Taunton Model Engineers Club track, Vivary Park, Taunton. This early test version used a crude volume control potentiometer to set the speed. This was allowed for testing, but it was made clear that a 'Dead Man's' function was a requirement so that with hands off, the loco would come to a halt.

The body shell had not been constructed, or even given much thought at this time.

Looking at all sorts of spring-loaded joystick and other possible arrangements for the controls of the finished locomotive, all complex and messy mechanical sketches were put in the bin and the whole control function was implemented using a touch-screen.

And finally for now, a couple of pics of the 'finished' loco, "The Wedge" !

Learning about and using Brushless motors has been fun, but it's only just begun! The next pic shows three motors rated at 105 Watt (four of these were used in the finished loco), 225 Watt and 650 Watt. More, and more powerful, electric locos in the pipeline, and, oh yes, the B1 also needs finishing !

Brushless - Motors with no holes in !

Have you ever been annoyed by motors with holes in? Holes, especially designed to let stray metalic objects in to get stuck to the magnets and generally bugger up the works.

Cheap and nasty brushed dc motors have holes in because they convert a lot of power into waste heat in the armature, close to the middle. Holes let air (and extraneous items) in to take heat away.

Brushless motors have windings on the stator - near the outside - where the heat can escape far more easily without using pesky holes !

This also explains why for any given rating, brushless motors are smaller, more compact and more efficient than horrible old brushed motors.